Our Design Process

Experts in modern, sustainable packaging

Find new possibilities in packaging

Creativity isn’t just about choosing a color and defining a shape. It’s about partnering together to create innovative, sustainable solutions.

Everyone has design ideas. But making packaging that’s unique and manufacturable takes expertise, technology and capabilities. Fueled by raw creativity and a long legacy in plastic bottle manufacturing, our creative team is obsessed with the balance between form and function. We design tailor-made sustainable packaging that delivers efficiencies throughout your supply chain. The end result is an easy-to-run bottle with consumer appeal that provides deep satisfaction for your customers.

Our Bottle Design Process

As a plastic bottle manufacturer, we follow a tried-and-true process that uses sound design thinking and applied imagination to match your product with the perfect packaging solution.

Discover

Gaining Insight

To make your brand stand out, we seek to understand the challenges you face, the goals you have and how you define success. We start with a clean slate, and then we review your design brief, exploring all possibilities in a collaborative environment. We employ brainstorming, conduct market research, assess production capabilities and utilize proprietary sustainability tools, all to guide you to the best possible solutions.

Design

Exploring Ideas

From the insights of discovery, ideas grow, and your solution begins to take shape. Our world-class design and engineering teams work with you remotely or in our welcoming Design and Innovation Studio to create sketches, renderings, real-time 3D designs and preliminary prototype models that bring your ideas to life. And through the power of collaboration during a live design session, you may walk away with a bottle design the same day.

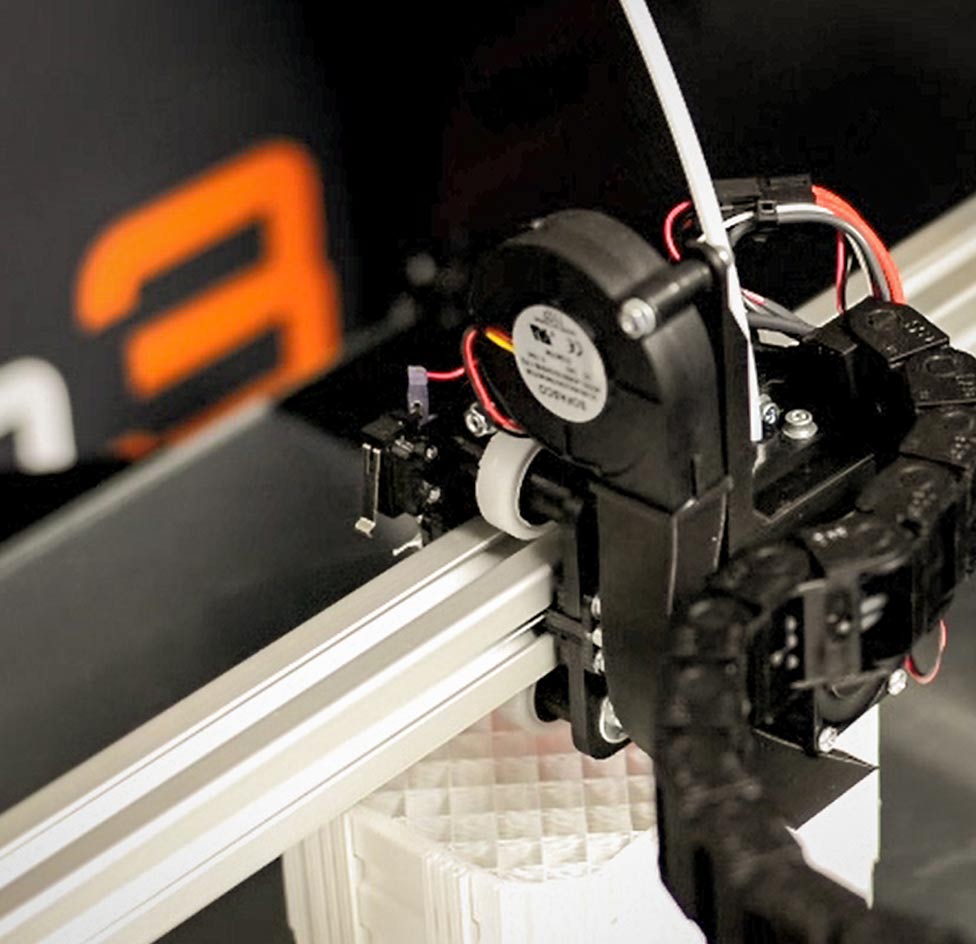

Develop

Refining Solutions

In this phase, the ideas become more structured as we align your design vision with the mechanics of production. The development continues with further refined 3-D surface and solid modeling, in-depth relief and texture studies and even free-form sculpting. From there we move to photo-realistic renderings, prototype models and technical concept drawings. Branding, consumer usage and shelf appeal are all in the mix to create the ideal design. Additionally, the ergonomics of the bottle are taken into consideration when developing the shapes.

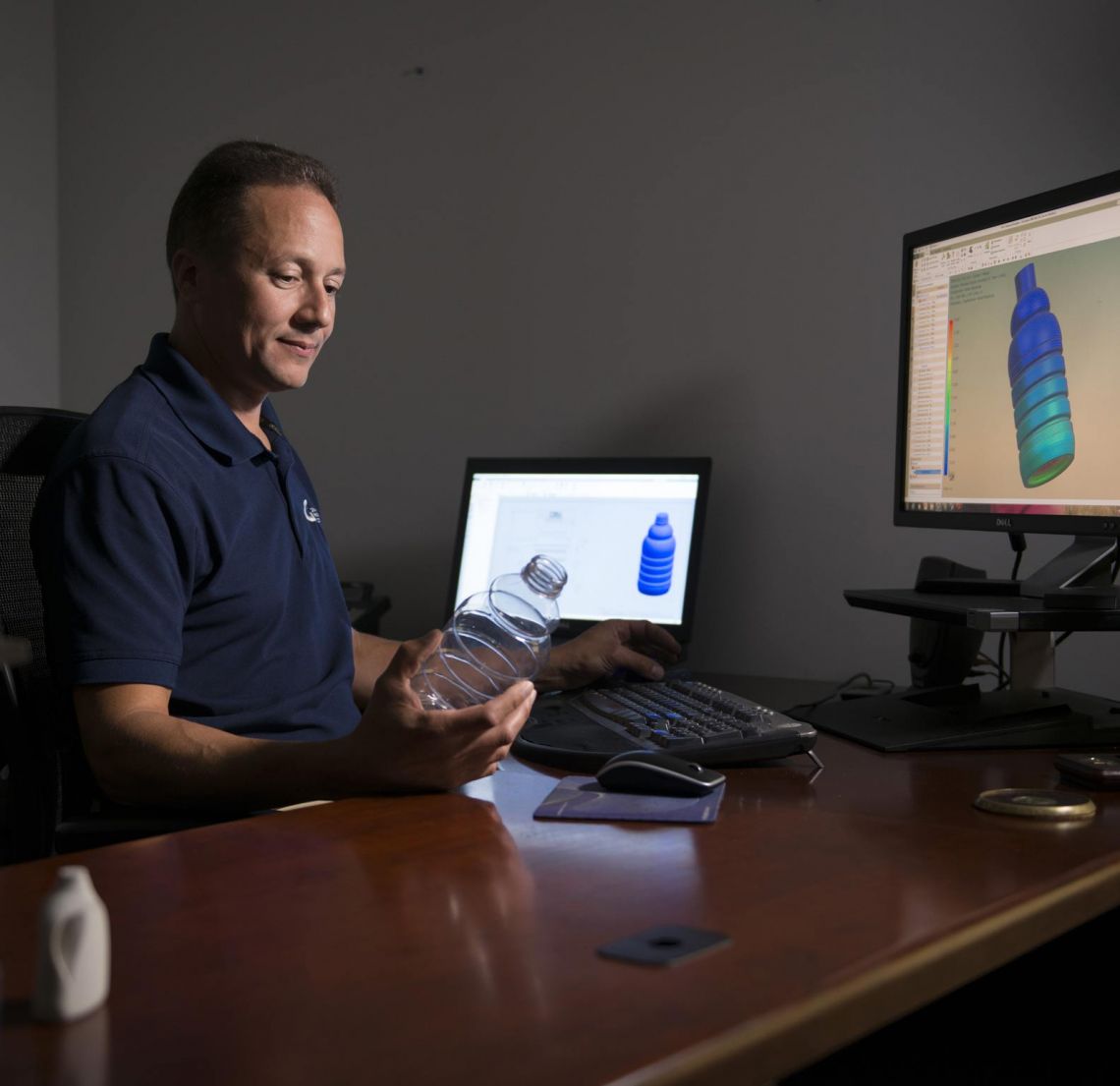

Determine

Testing Concepts

Now we put theory to the test and assure the production of your container is fully capable. We collaborate with you and use all the tools at our disposal to validate the concept. Design refinements, performance simulations and prototype blow molds are all part of this crucial process. If necessary, we will continue to improve your design until we reach the optimized solution.

Deliver

Producing Containers

At this point, all the boxes are checked, resulting in a unique container that has gone from specs to spectacular. Once the Graham team and your team are satisfied, we make final refinements, initiate article drawings and release production tooling. Product sampling is employed to guarantee the integrity and consistency of the final design. Then, your container makes a smooth transition into the pipeline where you get to reveal your new, production-ready packaging to customers.